MakerMade M2 CNC Kit

The ideal CNC machine for small business owners, DIYers and hobbyists, MakerMade M2 delivers a massive cutting area and advanced capabilities at th...

The ideal CNC machine for small business owners, DIYers and hobbyists, MakerMade M2 delivers a massive cutting area and advanced capabilities at th...

A 4 x 8 foot DIY CNC kit capable of making anything you can dream up. Based on Maslow CNC’s original design and endorsed by Maslow for distribution...

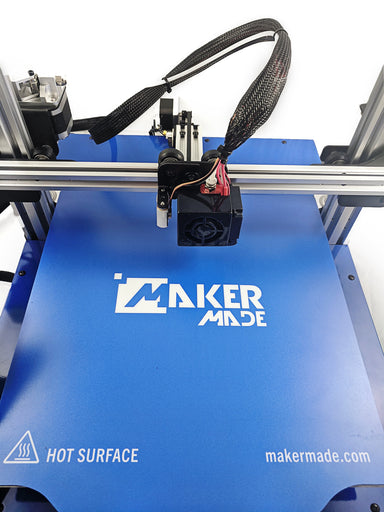

Unleash your creativity with the MakerMade 300x 3D Printer - the ultimate machine for bringing your ideas to life!With its high-precision print hea...

Conquer projects big and small with MakerMade's CNC Bundle! This Limited Availability Bundle includes one of our most popular CNC Kits and one of ...

Everything we love from the original Maslow kit PLUS a sled! A 4 x 8 foot DIY CNC kit capable of making anything you can dream up. Based on Maslow ...

Upgrade your M2 to laser engrave with the MakerMade 2.8w JTech laser and mounting kit. Your new laser will fit right into your current router clamp...

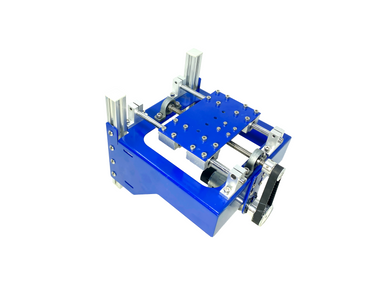

Introducing our compact and versatile MakerMade Mini CNC500 Machine! ***Select a Router/Spindle option below, or select "Neither" if you have your ...

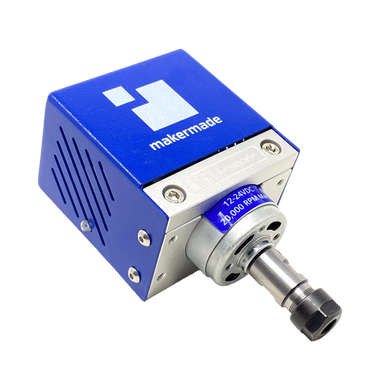

Introducing MakerMade Millie 775 Motor, a powerful 775 Spindle Motor specially designed for CNC500. Take your CNC projects to new heights with this...

Our best value and most serious bundle, this pro-grade pack of carbide, CNC router bits includes: 1 Up cut 1 Down cut 1 Compression 1 60/90 degre...

MakerMade's CNC Router with an ER-11 collet opens you up to a whole new world of router bits and End Mills not found on your standard hardware sto...

Solid aluminum mount for 65mm routers like MakerMade's CNC Router with ER-11 Collet, Makita RT0701, and Bauer Trim Router. Compatible with the M2,...

MakerMade M2 91mm Router Adapter Clamp with Bolts- the powerhouse tool for unbeatable stability and precision! For use with the M2 or M2 upgrade ki...

Get making BIG with MakerMade's Ultimate Maker Bundle! Back by popular demand, this Limited Availability Bundle includes our most popular tools at ...

Note: Not sure which bit is right for you? Check out our handy bit selection blog to make the right choice for your kit: Click Here!

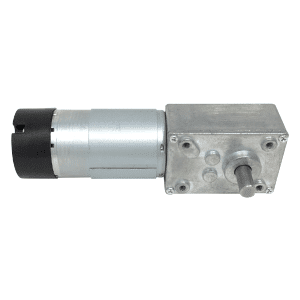

MakerMade CNC Z-Axis Motor (1) - the ultimate tool for precise and reliable movement of your CNC machine!Made with high-quality materials, this mo...

Take your CNC experience to the next level with the new camera module, designed by Obleek in partnership with MakerMade. Our HD 1080p 180˚ field-of...

Sold out

Sold out

STOP! This emergency stop button can be connected to the new safety compliant laser kits to immediately halt the laser in case of an emergency. St...

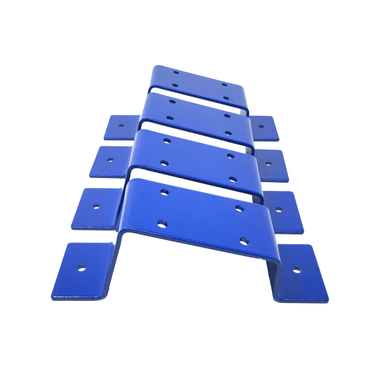

Save space in your CNC shop and time during setup with these M2 stud-mounts. These wall/frame brackets are the very first of their kind. Use to m...

MakerMade CNC XY Axis Motor for CNC kit- the game-changer for precision cutting! Crafted with the highest-quality materials, this motor delivers st...

Solid aluminum mount to secure your router. The front plate adjusts to accommodate varying sizes of routers. Compatible with 71mm size routers such...

3 of our MakerMade measurement products combined in one bundle, at one great price! The MakerMade Measurement Bundle includes our Tape Measure, Spe...

Includes three 1/8″ router bits (straight, up & down) with a collet reducer and case (not pictured). This is the same pack that comes with the M2.

MakerMade CNC Sled Ring - the ultimate accessory for precision and stability! Crafted with high-quality materials, this sled ring ensures stable a...

MakerMade CNC Z-Axis Motor Cable (1) - the ultimate accessory for unbeatable power and precision! Expertly crafted with high-quality materials, th...

The upgraded M2 DUE Board and shield are here to take your Maslow to the next level! Improved tech make this board a must for serious Maslow users...

Upgrade your Basic Maslow kit with this Z-Axis Upgrade kit. This Z-axis assembly can replace the Ridgid router base on your existing Maslow. Alumin...

Complete ring kit for Maslow and M2 CNC kits. Includes all mounting hardware and roller carriage components.

MakerMade CNC XY Motor Mounting Brackets (2) - the perfect accessory for precision and stability! Crafted with high-quality materials, these brack...

Standard 1/4" Compression Router Bit combines the fast cutting of the Standard 1/4" Upcut Router Bit with the clean edges of the Standard 1/4" Down...

Upgrade your CNC machine with the MakerMade M2 Dust Collecting Sled. This sled does not include the Sled Ring Kit. It is a SLED ONLY. MakerMade Sl...

Boost your machine's performance with the MakerMade CNC XY Motor Power Cables for CNC Kit - the essential accessory for precision cutting. Crafted ...

The MakerMade Chain Breaker is the ultimate tool for cleanly breaking chains with ease. With its innovative design and easy-to-use function, the Ch...

For mid- to large-scale projects, these bits are designed with a dual head for wider, 60- or 90-degree pockets. Great for Signs, Large Home Décor.

Crafted with the highest quality materials, this router bit features a unique compression design that helps prevent chipping and splintering of th...

Introducing the ultimate cutting tool for precision engraving and grooving projects! This router bit is crafted with the highest quality materials ...

Standard 1/4" Straight Cut Router Bit provides the clean edges of the Classic with plastic, acrylic and foam projects. Great for Signs, Acrylic she...

Enjoy a clean channel edge and upgrade your precision cutting game with the Standard 1/4" Downcut Router Bit! Its downcut design pulls chips and de...

Sold out

Sold out

Get the print quality of glass, with the adhesion of glue, and the easy removal of a peel-off sticker, all in one great 300x 3D printing bed mat. T...

When speed matters more than clean edges, Standard 1/4" Upcut Router Bit delivers a deeper plunge and faster carving. Great for Yard Art, Furniture...

Sold out

Sold out

Maslow/M2 CNC Universal Power Adapter - the ultimate power solution for unstoppable cutting performance! Expertly crafted with high-quality materi...

Crafted with high-quality materials, this single L-bracket ensures accurate and stable positioning of your machine, resulting in professional-grade...

Get the print quality of glass, with the adhesion of glue, and the easy removal of a peel-off sticker, all in one great NWA3D A5 3D printing bed ma...

Are you looking for a tool that can help you lift and move sheets of plywood and panels conveniently? If so, this plywood and panel lifter is perfe...

Upgrade your engraving game with MakerMade 1/4" Compression 90 degree V-groove Router Bit Engraver Series. With its 90-degree V-shaped cutting edg...

Engraver 1/4" Compression Bull Nose Router Bit combines the fast cutting of the Engraver 1/4" Upcut Bull Nose Router Bit with the clean edges of th...

3 of our newest MakerMade products combined in one bundle, at one great price! The MakerMade Accessory Bundle includes our Plywood and Panel Lifter...

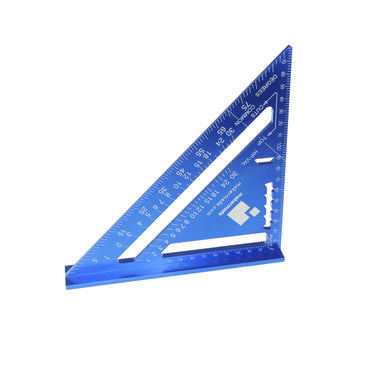

Our Speed Square is a versatile and accurate measuring tool for your CNC project. This triangular-shaped device assists with measuring angles and m...

Have a maker in the family and not sure what to get them? Purchase a MakerMade Gift Card as the perfect digital stocking stuffer! **The MakerMade...