Today we’ve got our next Maker Feature with Jamie from sharpsburg_woodworker on the Maslow forum.

Tell us about how you use your Maslow:

I went out to my shop one day and decided to design and cut out Christmas Yard Art Decorations. The project included drawing out the character on a sheet of plywood and then cutting the outline. I quickly discovered that I can’t draw, paint or cut a curved line. I wasn’t able to get a perfect cut on the project and it was difficult to draw the character.

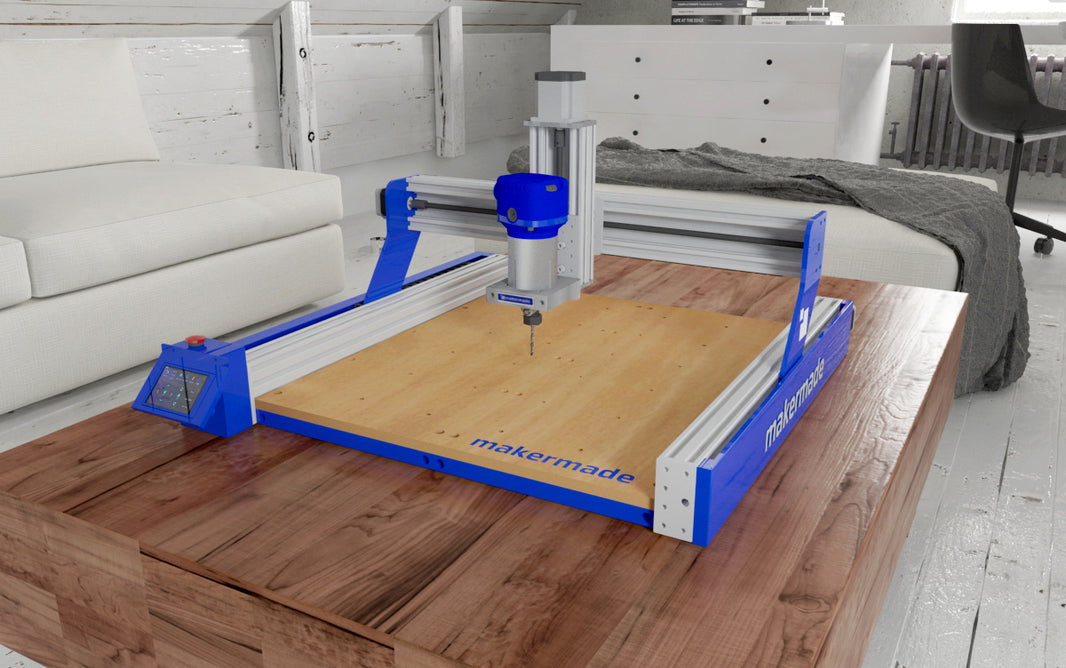

I saw Maslow CNC and instantly fell in love with this machine. I started saving money over 6 months and bought my CNC in the second batch. I quickly learned makercam and inkscape. I also learned onshape to help other creators on their projects.

I have a serious love for Christmas and host a full light show that is synchronized to music. I am fully invested in using my Maslow CNC for cutting out characters to fill up my whole yard. I use my marker holder to draw out the inner lines of a character and then switch to the router to cut the characters. My family all get involved with the painting. My oldest daughter paint up to the lines that create borders between colors. I later go back and simply paint out a black line to create a perfectly drawn out character.

My Maslow CNC has provided me with the tools to create and fulfill a lifelong dream. It enables me to overcome by poor artistic skills and create something that is amazing. It also allows me to teach my family about using a cnc and it allows us to enjoy building/creating together. My oldest daughter is now designing the cutouts on her own as well!

Tell us more about the marker holder you designed:

I tried alternatives that included an insert into the router itself. I finally designed a model that was cut on a lathe. However, I had problems with it binding in the router base. Kevin Keegan designed one that could be cut on the cnc. However, we had problems with the measurements. I eventually designed a maker holder with onshape. I 3D printed all the different layers until the measurements were perfect. My older model had loose tolerances that would create a pushed outline when it was lowered to the plywood. My current model has minimal tolerances that takes all the irregularities out of the drawing. The marker holder is 3d printed in a matter of hours and it will turn out perfect lines. The marker holder can be used for many applications. There are many designs (pic-nic table for example) that have many straight lines that have to be measured out and drawn. The CNC isn’t best used for cutting a lot of straight lines, but you could use the CNC to layout your cut lines on the board and then cut out the sections with a saw.

My next obstacle was how to create the tool paths. I create two sets of tool paths. The first tool path is always the inner lines. I had problems trying to convert an svg out of an image correctly. The inner lines and outer lines touch which would not allow me to create a good toolpath. I hand draw out all the lines with bezier curves on inkscape. It takes approximately 30 minutes to do each character, but I can correct any problems in this step. I then take this svg over to maker cam and create two tool paths. The first tool path is the inner lines and I use a follow path operation on all of these lines with a stepdown of .5 in and a total z axis drop of .5 in. This allows the marker tool to be dropped to the right depth and then draw the line in one pass for each closed line. I set the second tool path up as the outline with a profile cut. I found out that I had problems with lines that close up too tight for makercam to create a path. I utilized the outset function on inkscape to create a second outline that is outset by .25 in. I will do a follow path operation within makercam to cut the outline in this situation.

Thanks Jamie for sharing your story with us and for sharing your files with the Maslow community! To find Jamie on the Maslow forum and see his files for his Christmas cut-outs and marker holder design click here.