Printing

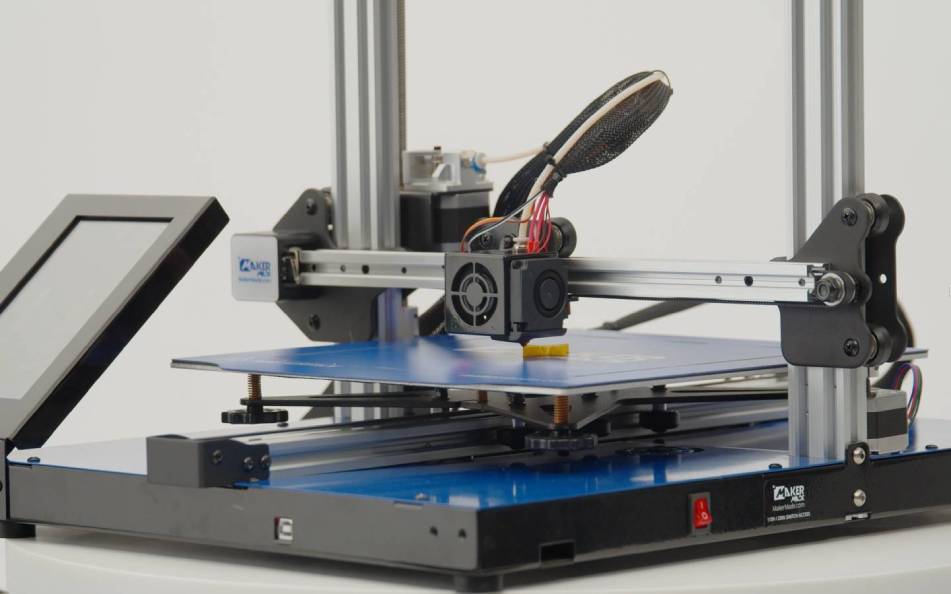

Technology: Material extrusion/FDM/FFF (fused deposition modeling/fused filament fabrication)

Build volume: 300 x 300 x 400 mm (12 x 12 x 16 inches)

Nozzle size: 400 microns (0.4 mm/0.015 inch)

Layer resolution: 80-300 microns (0.08–0.3mm/0.002–0.012 inch)

Heated bed: Yes

Build surface: Microporous flexible magnetic surface on anodised aluminum bed

Filament diameter: 1.75mm (0.069 inch)

Filament material compatibility: PLA, HTPLA, TPU, PETG

Mechanical

Weight: 15kg (33lbs)

Overall size: 50cm x 59cm x 63cm (19.5″ x 23.5″ x 24.5″)

Construction: Rigid, 100% all-metal structure

X and Y motions: V-track belt system

Z motion: Double Z-Axis motors and leadscrews

Extruder: Bowden Style, Dual-Gear Single Extruder

Maximum nozzle temperature: 260°C (500°F)

Maximum bed temperature: 110°C (230°F) (*Note: the magnetic build surface will demagnetize above 75°C)

Electrical

Power: 110v/220v input; 24 volt, 15 amp output

Printer Control Board: MKS Gen L v1.4

Stepper Drivers: Trinamic TMC 2208 v2

Raspberry Pi: 2GB 3B+

Interface: 7″ Full-color LCD touchscreen

Connectivity: USB cable, USB Drive, Wi-Fi

Firmware: Custom Marlin 2.0

Software

Slicer: Makerverse Compatible (Any generic G-code slicer works)

Slice file format: Gcode

Printing

Mechanical

Electrical

Software