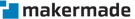

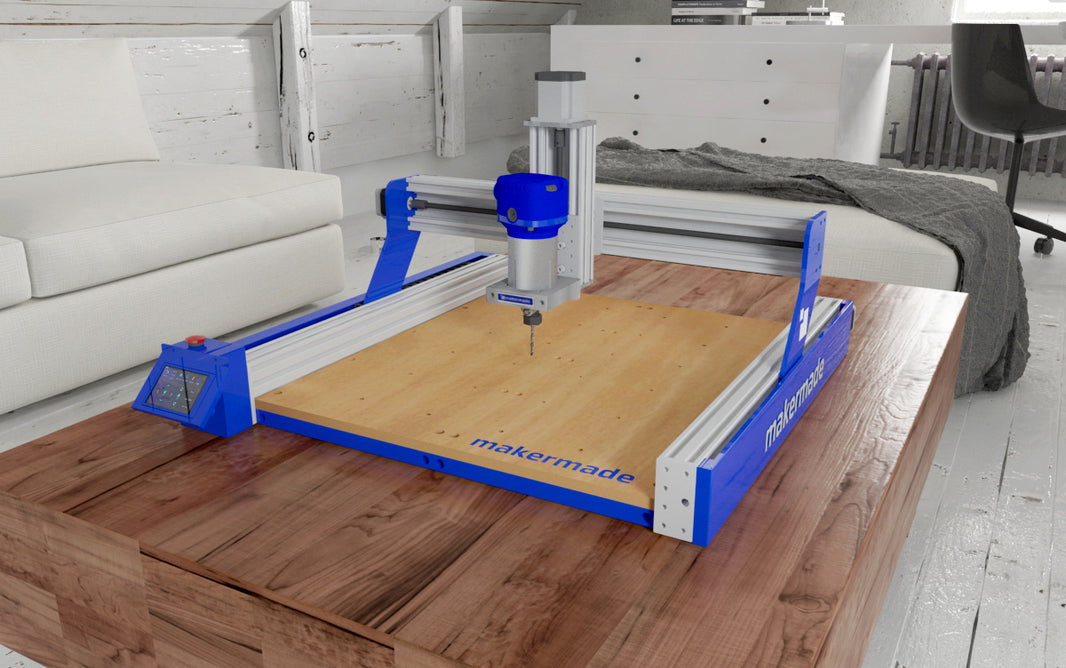

In this article, we will be walking you through all the things you need to know in order to start beta testing the 7W J Tech laser module on your MakerMade CNC Machine. It is important to state that this beta test is for experienced MakerMade CNC users. The current phase of this beta test will consist of you sourcing all parts you will need to get started. We will provide you with a list of those parts below as well as assembly instructions.

If you are not interested in beta testing and sourcing these parts, please head over to our Laser Kit preorder product page on our website (Maslow Laser Upgrade/M2 Laser Upgrade) and you’ll receive everything you need to install a laser on your CNC Machine in just a few weeks!

Now that you have watched the video and gotten a sneak peek of the laser in action, let’s talk about what parts you will need!

M2 Due Board |

If you have an M2 then you should already have a Due Board. But if you have a Maslow CNC and have not purchased an M2 due board as an upgrade for your Maslow, please follow this link to purchase, as you will need this to use the laser module. |

J Tech Generic All-in-One Laser and Mounting Kit Bundle |

We provide support for the 7W laser module designed and sold by J Tech. On J Tech’s Laser Kit product page it has multiple drop down boxes for you to customize your kit. Lets go through what options you need to pick for each drop down box! Laser Power: 7W Magnetic Shroud Upgrade: Yes Laser & Fan Extension Cable Length: 15ft Power Cord Option: Pick the region where the laser will be used Add High Resolution Lens: Optional Click here to order now! & Use coupon code makermadelaser10% to get 10% of your purchase! |

Customized Mount |

Our team has designed a custom mount (for the 7W laser) STL file that will need to be printed on a 3D printer. If you do not have access to a 3D Printer, email us at info@makermade.com to inquire about purchasing a mount from us. There are also companies such as ShapeWays that can provide you with 3D printer services. |

1K ohm Resistor |

You will also need to a single 1k ohm 1/2w (0.5Watt) ±1% Tolerance Metal Film Fixed Resistor in order to have your laser module up and running. You can purchase this at your local electronics store, or in bulk online. Click here to order now! |

Software Required to Run Your Laser Module

You will need Lightburn (GRBL-based version) to make the CAM file. You can purchase this software for a one time fee of $40.

You can then import the G-Code into Makerverse to run on the CNC. Ensure that you are using at least Makerverse version 1.1.2 or any versions above that.

View Our Assembly Guides

Please make sure that before starting up your laser that you read the safety disclaimer in order to be as safe as possible while running your CNC machine.

Frequently Asked Questions

Yes!

Use coupon code makermadelaser10% for 10% off.

The CNC machines are currently only compatible with the Generic 7W All-in-One Laser from J-Tech. We will be offering compatibility with the 2.8W and 4.2W laser soon! Use coupon code makermadelaser10% for 10% off!

Yes! We have a preorder product page for both the Maslow Laser Upgrade & M2 Laser Upgrade at a special price. The Laser Upgrade Kits will ship by July 1st.

We highly recommend having a separate sled option for laser engraving and cutting. A dedicated laser-engraving sled provides a convenient transition between router use and laser use, and also maintains the integrity of the laser mount holes, which can become stripped after multiple detachments and reattachments of the mount. Multiple detaching and reattaching of your laser mount will strip the wood holes needed to hold the mount in the center of your sled and may result in the laser becoming dislodged, causing potential damage and/or injury.

Yes, the laser will work with the Basic Maslow sled, as long as you have a DUE board installed.

For purchasing and installing the DUE board, please follow this link.

You will need the DUE board. If you have the M2, there’s no need to purchase a DUE board. For purchasing and installing the DUE board, please follow this link.

No, the laser can be attached without removing the z-axis. You can view the full instructions here.

We highly recommend having a separate sled option for laser engraving and cutting. A dedicated laser-engraving sled provides a convenient transition between router use and laser use, and also maintains the integrity of the laser mount holes, which can become stripped after multiple detachments and reattachments of the mount. Multiple detaching and reattaching of your laser mount will strip the wood holes needed to hold the mount in the center of your sled and may result in the laser becoming dislodged, causing potential damage and/or injury.

You will need to remove your router clamp when you first install the laser mount. You can view the full instructions here.

We highly recommend having a separate sled option for laser engraving and cutting. A dedicated laser-engraving sled provides a convenient transition between router use and laser use, and also maintains the integrity of the laser mount holes, which can become stripped after multiple detachments and reattachments of the mount. Multiple detaching and reattaching of your laser mount will strip the wood holes needed to hold the mount in the center of your sled and may result in the laser becoming dislodged, causing potential damage and/or injury.

Our team has designed a custom mount STL file (for the 7W laser) that will need to be printed on a 3D printer. If you do not have access to a 3D Printer, email us at info@makermade.com to inquire about purchasing a mount from us. There are also companies such as ShapeWays that can provide you with 3D printer services.

Depending on specific laser, the laser can potentially engrave or cut acrylic, paper stock, wood, glass, aluminum, foam board, leather, circuit boards, some plastics (NEVER vinyl!), fiberglass, carbon fiber, etc. Here are the links to J Tech’s Laser Engraving Applications and Unsafe/Safe materials.

The cutting/engraving depth varies depending on the power intensity of the laser and the material you are cutting/engraving. The depth can range from 4 inches on foam, to 1/8 inch on balsawood. Density, color, and thickness of material will affect results. Multiple or front & back passes may be required to achieve your desired depth.

During operation, avoid direct exposure to the beam. When choosing the material to cut, please refer to the safety disclaimer and choose the proper materials. Please pay extra attention in choosing the right plastic to cut, as many plastics will melt, catch fire, or create very toxic fumes!

All design files in SVG format can be transformed into a CAM file in Lightburn, and processed in Makerverse for laser cutting.

No, there is no additional calibration needed for the laser. If you’re calibrated for the router, you’re calibrated for the laser!

Because of the power of the 7W laser, J-Tech requires purchase of the magnetic shroud for the 7W laser for safety. If you purchase through J-Tech, you will need to select the shroud, though you will not need the associated magnetic mount with our kits.