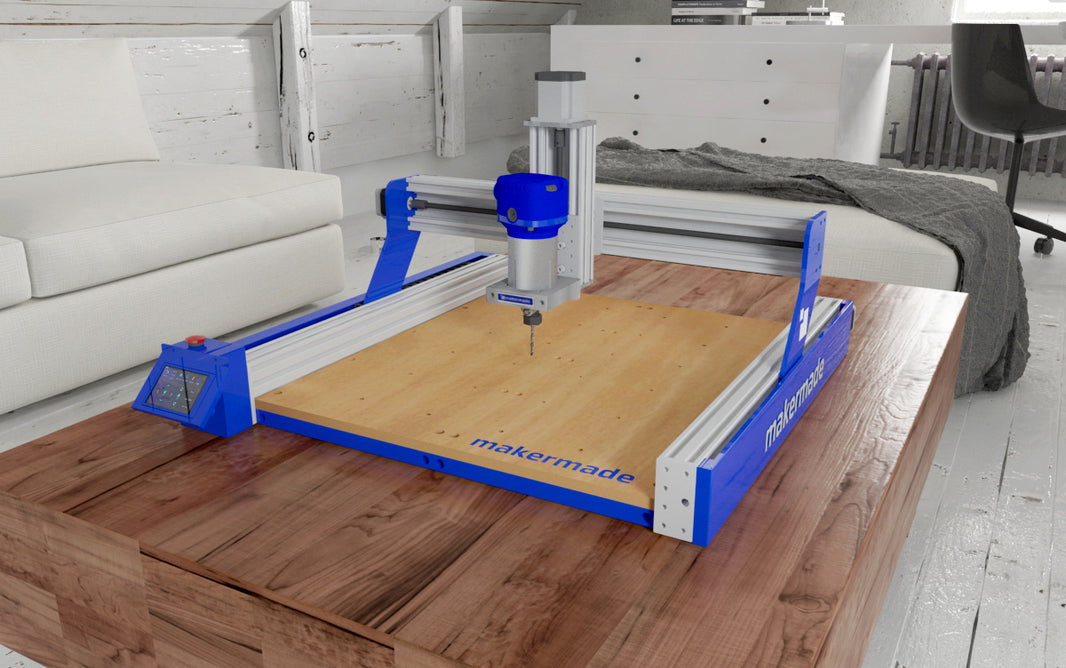

One of our fantastic content creators, Jared, recently received a custom order at his business, which demanded him to be creative and out-of-the-box, which he succeeded at.

When asked to make a mountain-shaped shelf for rock collection that currently held close to 50 rocks, with some as large as 4”, he knew he needed to be innovative about the shelf’s design.

After some creative design work, Jared and the customer decided on the look that you see below:

He started with a 1/8in up-spiral bit (making good use of a collet reducer on his router) but had to make the change to a 1/8in compression bit for a cleaner cut edge. After beginning his project, he had problems cutting on a 4×8 sheet, so he improvised and cut it in half to make two 4×4 sheets. Then, he added a border to his machine to give it more stability while cutting near the edge of the piece:

To really perfect the accuracy across so many matching components, he added a 12-foot top beam and moved it up to 2-feet from the top of the work surface, which allowed the sled more stability across the surface. In the end, the shelf was comprised of eight layers of 3/4in pre-finished Radiata Pine Plywood, stacked together and glued to make a six-inch shelf, capable of holding his customer’s impressive rock collection:

The project took just four hours from start to finish, and looks tremendous!

Jared is always creating something new with his CNC, and you can find more of his creations on his Instagram, @deraj91.