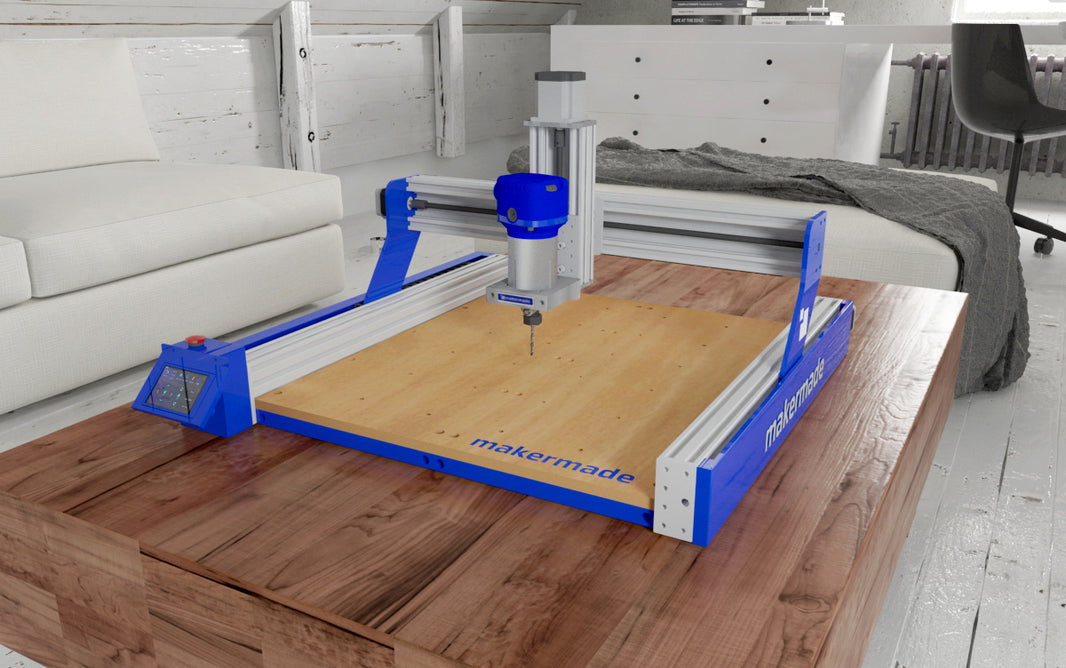

If you have your Z-Axis set up and the calibration step went well, you shouldn’t have any problems cutting the final sled. I ended up getting a prototype of the new MakerMade sled in the mail, so I used that, and it was so nice to have it all ready to go. I just had to add a few holes for the bolts that hold the router into place. The sled doesn’t come with those holes pre-drilled because not everyone uses the same router.

I had kind of improvised with my temporary sled, I’d used a tabletop round, and gone with a smaller size than recommended because I liked the idea of a more compact sled. I’d also put my weights in a different position. Once I got this sled set up, though, I realized that some of the problems I’d been having up to that point were because of my sled. Everything moved so much more smoothly once I had a perfectly balanced sled, and I think the larger size helped stabilize movement, too.

In the Maslow forum, you’ll see that people use all kinds of things for weights. You might think that anything goes, and that’s true, to a point. But make sure that whatever you used, your weights are symmetrically balanced on the sled, and they don’t dangle or move as the sled is moving. I’m a tinkerer at heart, and I like to improvise my own solutions. One thing I’ve learned over and over, though, is that often, it pays to do it the way more experienced people have done it first, then, once you understand what’s going on, you can improvise. So many I’ve looked at something and thought, “Why did they do it like that? It’d be so much better/ easier like this,” and so many times I’ve learned the hard way that there were good reasons for doing it the way the recommended way. Once you get a little experience under your belt, you can start to improvise your own solutions, but maybe try it the default way first.

Tools Needed

- Router, .25” router bit

- Screwdrivers

- Power Drill, .25” drill bit

- Sandpaper

- Socket wrench, various sizes

- 5/16 Allen Wrench

- Pencil

- Safety goggles

- Clamps (optional)

Materials List

- (1) 4×8 plywood, .75” thick*

- (2) bricks **

- (3) Size 10-32 machine screws

- Hardware and parts from kit

Cut List

- (1) 18×18” circle

- (2) 1×5.5” rectangles

- If using MakerMade metal brick holders or pre-made sled these pieces aren’t needed

*If you have scrap plywood on hand, it’s not necessary to buy a whole sheet of plywood

**If using MakerMade metal brick holders bricks should be no more than 4.5” wide

STEP 1: GENERATE G-CODE FOR SLED FILES

- Download sledfiles.zip at

Github/MaslowCNC/Mechanics/SVG Files - Unzip folder, locate svg file for sled- New Sled With Tool Paths.svg

- Open makercam.com in a browser window

- Click FILE->OPEN SVG File, select sled file, shapes should open up as shown on left

- This file already has toolpaths set, so click CAM->CALCULATE ALL

- Blue paths will appear, showing path of the router, green arrows indicate cut direction

- Click CAM -> EXPORT GCODE

- Click SELECT ALL to select all of the paths

- Click EXPORT SELECTED TOOLPATHS

- Save to your desktop as .nc file

STEP 2: LOAD PLYWOOD ONTO MASLOW

- Hang sled on bolt in center of top beam to keep it out of the way

- Load plywood onto frame

- Remove sled from bolt and gently bring it to rest against plywood

- A full sheet of plywood is not necessary but may be easier to work with

- This is a SECOND piece of plywood, in addition to the plywood used as backing for your frame

STEP 3 OPEN FILE IN GROUND CONTROL

- Click ACTIONS-> OPEN FILE

- If using scrap plywood it may be necessary to reposition the design

- Move sled to desired position on plywood using arrow keys in top right corner of Ground Control

- Sled will be cut to the left and down from beginning sled position

- When router is in desired position, click DEFINE HOME

STEP 4 CUT THE SLED

- Turn router on

- In Ground Control, click green arrow button

- Router will move through pattern

- Do not leave Maslow unattended while work is in progress

- If you need to leave for any reason, click yellow pause button, turn router off

- If shapes appear off, click red stop button and troubleshoot

- If you began the cut, then stopped because it was off, when you start again you can move your sled to a new area of your plywood, then re-define HOME

STEP 5 ASSEMBLE FINAL SLED

- Once pieces are cut, turn router off

- Hang temporary sled on bolt in top beam

- Remove chains from carriage mounts

- Remove sled from bolt, set on workbench

- Remove bolts holding bricks, router, and ring kit to temporary sled

- Transfer everything to final sled, referencing instructions in Temporary Sled section if needed

- Sled will slide across the work area more smoothly with a rounded edge

- Use sandpaper to round the edge

STEP 6 ATTACH FINAL SLED TO FRAME

- Hang final sled on bolt in top beam

- Attach chains to sled, referencing instructions in Temporary Sled section if needed

- Remove sled from bolt and gently lay against work surface

- You’re now ready to begin making amazing projects!!