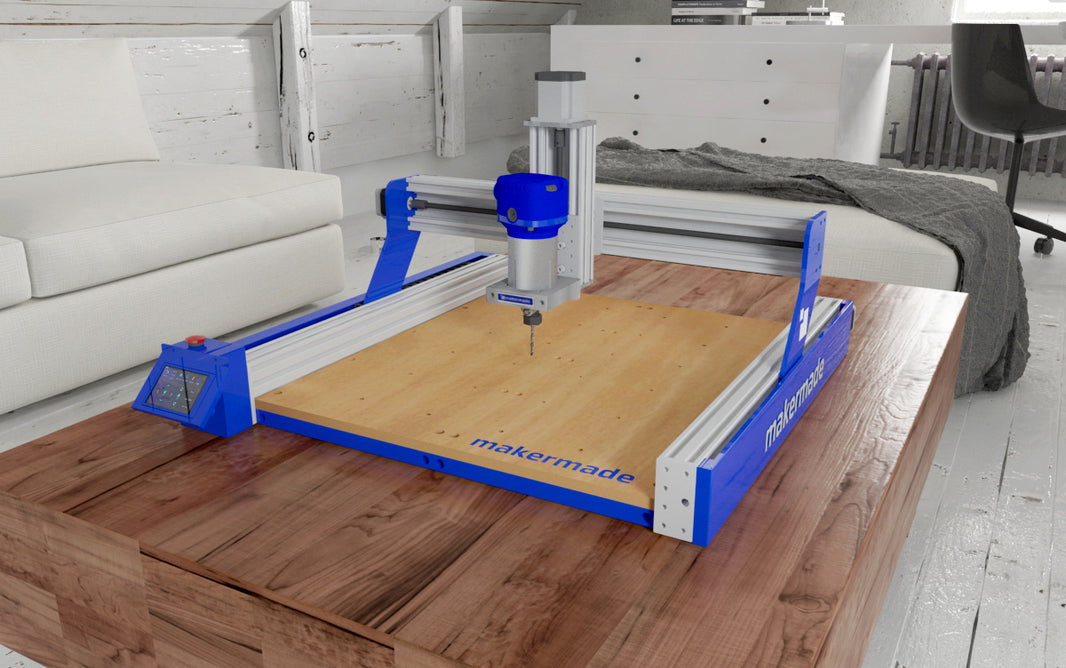

One of the things that makes the. Maslow CNC so affordable is that each user builds their own frame. Maslow users are tinkerers, and variations on the frame are endless. Two users, dlang and MadGrizzle, did a lot of testing and weeding through ideas and developed the default frame. It’s a great frame to start with. Bar, one of the original Maslow developers, also came up with a version of the default frame that bolts together, rather than using glue and screws. I decided to go with the bolt together frame, because I like the idea that of being able to disassemble the frame a little more easily if I want to move it, and because it worked better with the 2x4s I already had on hand. You can read the build instructions I wrote for the default frame here. The bolt together version of these instructions will come out soon.

I headed to Home Depot and got the bolts I needed, along with a couple of 2x4s to round out what I already had. I felt a little self conscious at Home Depot- on a weekday morning it feels like everyone else in the lumber department is a legit construction worker. I kept waiting for them to laugh at me for doing something clueless, but really, I think they were all just going about their business not paying me any attention. I got what I needed, headed home, and got set up to work.

The bolt together frame is pretty simple if you have a power drill. The one part that presents a little difficulty is the part where you need to drill through the long end of a 2×4. There are a lot of suggestions in the forums for making that easier, and the one that appealed to me the most was to make a guide out of Legos

I was super nervous after reading about how hard it would be to drill this hole straight, so I practiced first on a scrap piece of wood, then used that piece as a guide for drilling the actual hole

I probably overused the clamps, but the hole came out impressively straight.

I didn’t take a ton of process pictures, because there are a lot of those pictures already available in the forums, and it didn’t seem like there’s anything new I could add. It went together fairly quickly, and pretty soon I had a shiny new frame!

I did run into a problem the next day, though. The plywood warped pretty badly. I don’t know if I used the wrong kind, or if it’s just that I live in Virginia and it’s hella humid

I decided that if I could force it to lay flat, then screw it into place while flat, the problem would be solved. I enlisted recruits to help me

We forced the board into submission and screwed it down on both sides. It seemed pretty solid. But the next morning it was bowed again. I had overlooked the obvious- that in the bolt together design, the plywood backboard is the only thing holding the sides apart, so if it wants to bend, it can just pull the sides closer together.

I fixed that by cutting an extra 2×6 I had on hand and screwing it in place across the bottom.

I also bought a new plywood board and screwed it down before it had a chance to warp. I could add another cross beam across the top, but so far the bottom beam has been enough to keep things straight. I don’t have extensive carpentry experience, obviously, and this was a pretty easy build.

Tools Needed

- Saw

- Screwdriver or Power Drill

- Square

Materials List

- (7) 10’ long 2×4’s*

- (1) 8′ long 2×4

- (1) 6’ long 2×4

- (2) 4×8 sheets of plywood**

- (2) bricks (various sizes will work)

- Wood glue

- (75-100) 2 1/4 in wood screws

* If 2x4s are not available in your area the equivalent works

**If you have scrap plywood on hand, you may only need (1) 4×8 sheet of plywood, see cutlist

Cut List

2 x 4’s

- (1)120”

- (1) 88”

- (2) 82”

- (2) 79”

- (2) 60”

- (2) 34”

- (2) 30”

- (2) 28”

- (2) 7”

- (4)3.5”

Plywood

- (1) 4×8 full sheet

For Temporary Sled

- (1) 18×18” square

- (2) 1×5.5” rectangles

For Final Sled

- (1) 18” diameter circle

- (2) 1×5” rectangles

ASSEMBLY- Note: All joints should be glued as well as screwed

STEP 1: ATTACH KICKERS TO FRONT LEGS

- Kickers at 90° angle to front legs

- Kickers 11.5” from bottom of front legs, and hanging over by 1.75”

- Screw through top of kickers into front legs

- Screw through top of kickers into spacers

STEP 2: ADD BACK LEGS

- Flip assembly over

- Center back leg over front leg

- Align bottom of back leg with front leg

- Screw through top center of back leg into front leg- 1 screw only per leg

STEP 3: POSITION BACK LEGS

- Rotate back legs out to end of kickers

- Screw bottom of back legs to kickers

- Add more screws to top of back legs

LEGS ARE NOW COMPLETE!

Next steps are most easily done with front leg horizontal to floor, as shown. Prop with scraps to keep things level.

STEP 4: ATTACH LOWER FRONT CROSSMEMBER

- Rest lower front crossmember on kickers

- Screw from top of crossmember into each kicker- see Figure 1

- Screw from side of each front leg into crossmember- see Figure 2

STEP 5: ADD SPACERS

- Use verticals to measure placement of spacers on inside of front legs

- DO NOT ATTACH VERTICALS IN THIS STEP

- Screw through spacers into front legs

STEP 6: ATTACH UPPER FRONT CROSSMEMBER

- Rest upper front crossmember on spacers

- Screw through sides of front legs into crossmember

STEP 7: ATTACH VERTICALS

- Use diagonals to place verticals

- DO NOT ATTACH DIAGONALS IN THIS STEP

- Screw through top crossmember into verticals

- Screw through bottom crossmember into verticals

STEP 8: ATTACH DIAGONAL BRACING

- Rest diagonals with one end on front leg, one leg on upper crossmember

- Screw diagonals in place on each end

- Placement of diagonals need not be exact

STEP 9: ATTACH REAR CROSSMEMBER

- Rest rear crossmember on top of kickers where they protrude from back legs

- Screw through rear crossmember into back legs

STEP 10: ATTACH SIDE BEAMS

- Beams should have one factory end

- This end should face out

- Place one beam at a 90° angle to each front leg

- Screw through beams into front legs

11: ATTACH TOP BEAM

- Center top beam across front

- Screw through top beam into 7” beams on each side

STEP 12: STAND UP FRAME & ATTACH PLYWOOD

- Rest plywood on kickers

- Attach with screws through front of plywood into each front leg

You now have a complete frame!

NEXT STEP: ADDING THE ELECTRONICS

This work is licensed under a Creative Commons Attribution-NonCommercial-NoDerivatives 4.0 International License.